We monitor the quality of the products very close at each stage of the process. This is all based on our risk analysis.

- Contracts with local farmers

- Field inspections of the crops

- Entry control of raw materials

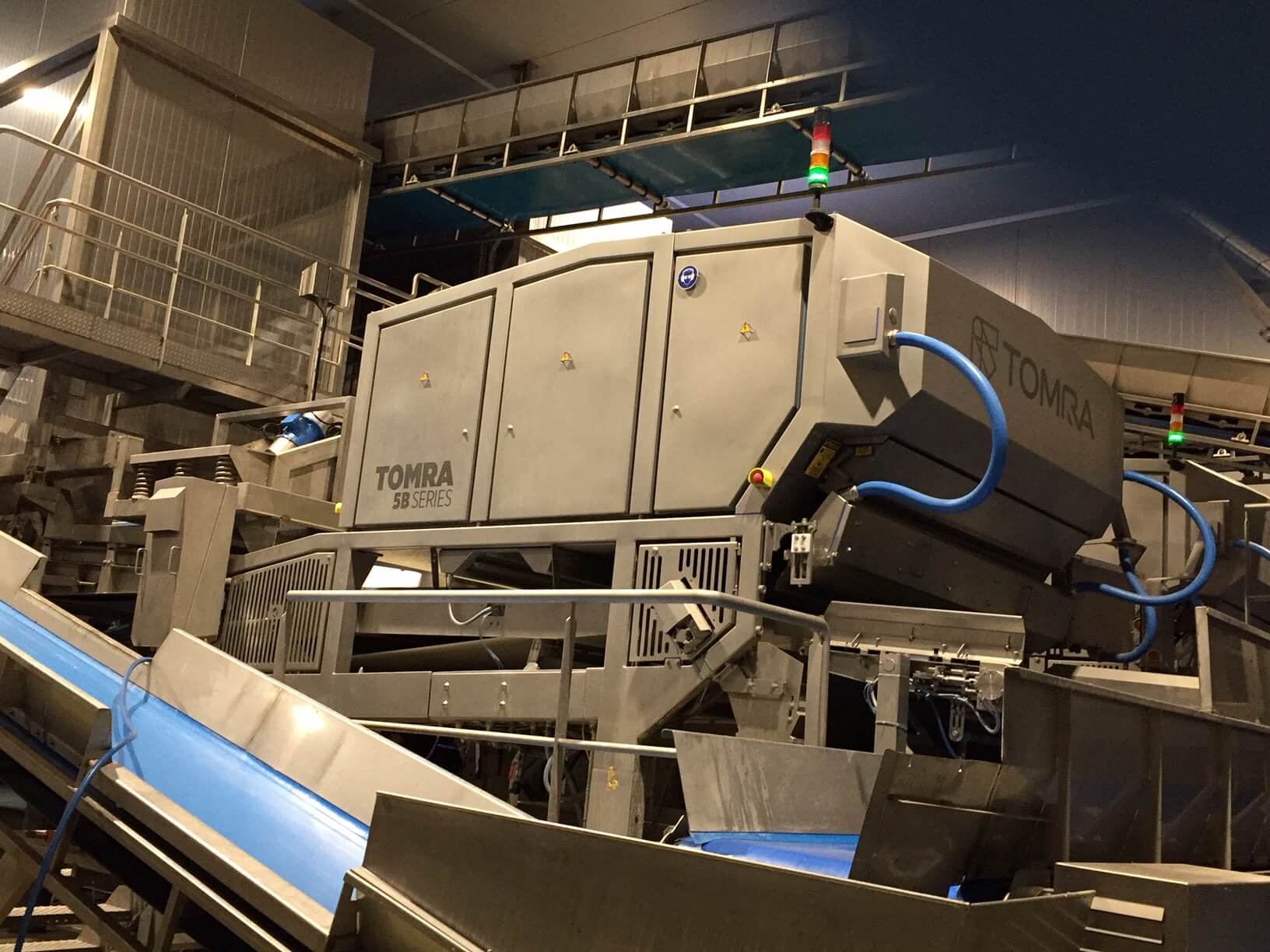

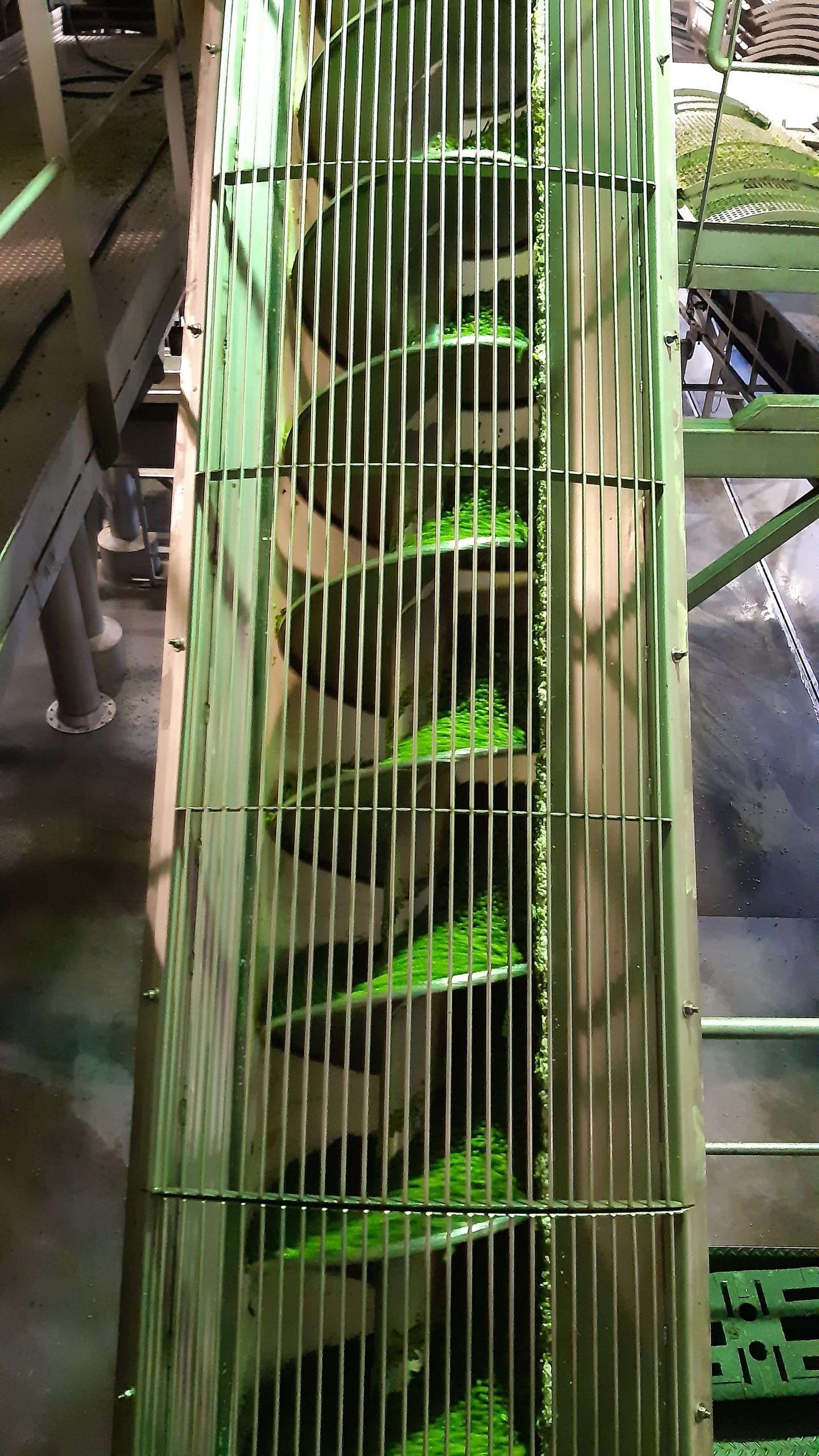

- Follow up the production process: different machines for each type of vegetable to remove quality defects and foreign bodies.

- Checks of the semi-finished product

- Follow up the packing process: quality product and packaging, setting and checks of different machinery as optical sorter and metal detector.

- Loading checks

- Our products are analysed on microbiology, pesticides and heavy metal according to our sampling plan.